Last month, a repair shop owner in Texas called me in a panic.

He'd just installed 50 iPhone 12 screens from a new supplier. The price was right—20% below his usual source. The screens looked perfect. Even passed his basic visual inspection.

Within a week, 12 customers came back complaining about eye strain and "weird flickering" at low brightness. His Yelp rating dropped from 4.8 to 3.2. He lost $8,000 in refunds and screen replacements, plus probably $50,000 in future business from the reputation damage.

All because he didn't know the one test that takes 30 seconds.

I've been sourcing screens from Huaqiangbei for over 10 years. I've seen this story play out hundreds of times. The repair shop owner chases a good price, skips proper testing, and ends up paying triple—once for the bad screens, again for the returns, and a third time in lost customers.

Here's what I'm going to share with you today: the exact 3-minute testing protocol I use for every screen shipment, plus the Chinese phrases that instantly reveal whether you're talking to a factory or a middleman. This is the stuff you won't find on Reddit or YouTube—because the people who know it are too busy making money to post about it.

The $12,000 Mistake (And How to Avoid It)

Let me tell you about the Florida shop owner. Names changed, but the numbers are real.

He ordered 200 iPhone 11 screens from a supplier offering prices 20% below market. The supplier had good reviews on Alibaba. Responded quickly on WeChat. Even sent sample photos that looked legitimate.

The screens arrived. They looked perfect. Passed basic visual inspection. The first 50 installations went fine.

Then the returns started.

Customers complained about "weird colors" and "eye strain." The shop owner thought they were being picky. Until he got a call from an optometrist whose patient developed persistent headaches after getting their screen replaced.

The screens had PWM flicker at 120Hz—half the safe threshold. The supplier had bought factory rejects (called "混货" or "mixed goods" in Huaqiangbei) and relabeled them as first-quality.

Total cost:

- 147 screen replacements: $4,410

- Labor for reinstalls (at $20/screen): $2,940

- Refunds for customers who didn't return: $1,800

- Lost future business (conservative estimate): $3,000+

- Total: $12,150

The lesson? A 30-second slow-motion camera test would have caught this before he accepted the shipment.

The 3-Minute Test Protocol

Here's the exact testing sequence I use for every screen shipment. Takes 3 minutes, catches 95% of quality issues.

Test 1: The Black Room Test (60 seconds)

This test separates real OLED from LCD screens mislabeled as "Hard OLED"—a scam that's more common than you'd think.

What you need: A dark room (bathroom with lights off works fine).

Steps:

- Take 5 random screens from the shipment—not the ones on top.

- Power each screen and go to

darkblackscreen.com. - Set brightness to 100%.

- Look at the screen in complete darkness.

What you're looking for:

- True OLED: Completely black. No glow. You shouldn't be able to tell the screen is on.

- LCD mislabeled as OLED: Faint grayish glow, especially visible at the edges. This is backlight bleed—LCD screens can't turn off individual pixels.

The rule: Any glow = reject the entire batch. If they're mislabeling LCD as OLED, what else are they lying about? I've caught three suppliers in the past year selling Incell LCD screens as "Hard OLED" at OLED prices. The black room test takes 60 seconds and saves thousands.

Test 2: The Slow-Mo PWM Test (60 seconds)

This is the test that would have saved the Florida shop owner $12,000.

PWM (Pulse Width Modulation) is how screens control brightness. Instead of dimming the backlight, they flicker the pixels on and off rapidly. At high frequencies (3000Hz+), nobody notices. At low frequencies (below 240Hz), 10-15% of people get eye strain, headaches, and fatigue.

Cheap screens often have terrible PWM. Here's how to catch them:

What you need:

- Any phone with slow-motion video (240fps or higher).

Steps:

- Set the test screen to 25% brightness (PWM is worst at low brightness).

- Open your camera app, switch to slow-mo (240fps).

- Point at the screen and record for 10 seconds.

- Play back the video.

What you're looking for:

- Good screen: Minimal or no visible flickering.

- Bad screen: Obvious dark bands rolling across the screen, or the whole screen visibly pulsing.

The rule: Visible flickering at 240fps = dangerous PWM. Reject.

Here's the insider knowledge: Original Apple OLED displays run PWM at around 240Hz at low brightness, but Apple's implementation includes additional smoothing that minimizes the impact. Cheap aftermarket screens often run at the same frequency without the smoothing—same spec on paper, completely different experience for customers.

Test 3: The Supplier Verification Test (60 seconds)

This test doesn't check the screen—it checks the supplier. And it's the most important test of all.

The WeChat Test:

Send this message to your supplier:

"这批货是哪个厂的?" (Which factory is this batch from?)

What their response tells you:

- Immediate answer with factory name: Probably legitimate. Follow up by asking for the factory's business license number.

- Vague answer ("top quality factory," "our partner factory"): Middleman. They don't know because they're buying from whoever has stock.

- Deflection ("why do you need to know?"): Run.

The 2am Test:

Here's something nobody talks about: message your supplier at 2am Beijing time.

- Response within 5 minutes: They're a middleman working from home, not a factory with business hours.

- Response next morning: More likely to be a legitimate operation.

Middlemen aren't necessarily bad—but they can't guarantee consistency between batches because they're sourcing from whoever has the best price that week. If quality consistency matters to you, you need a factory relationship.

The Price Test:

If a supplier's price is more than 15% below market rate, ask yourself: why?

The answer is usually one of three things:

- Factory rejects (混货) relabeled as first-quality.

- Refurbished screens (后压屏) sold as new.

- They're losing money to get your first order, then will raise prices or drop quality.

In Huaqiangbei, we call the newcomer markup "杀熟价"—literally "killing the familiar price." New buyers pay more until they prove they know the market. But if you're getting prices way below market as a new customer? Something's wrong.

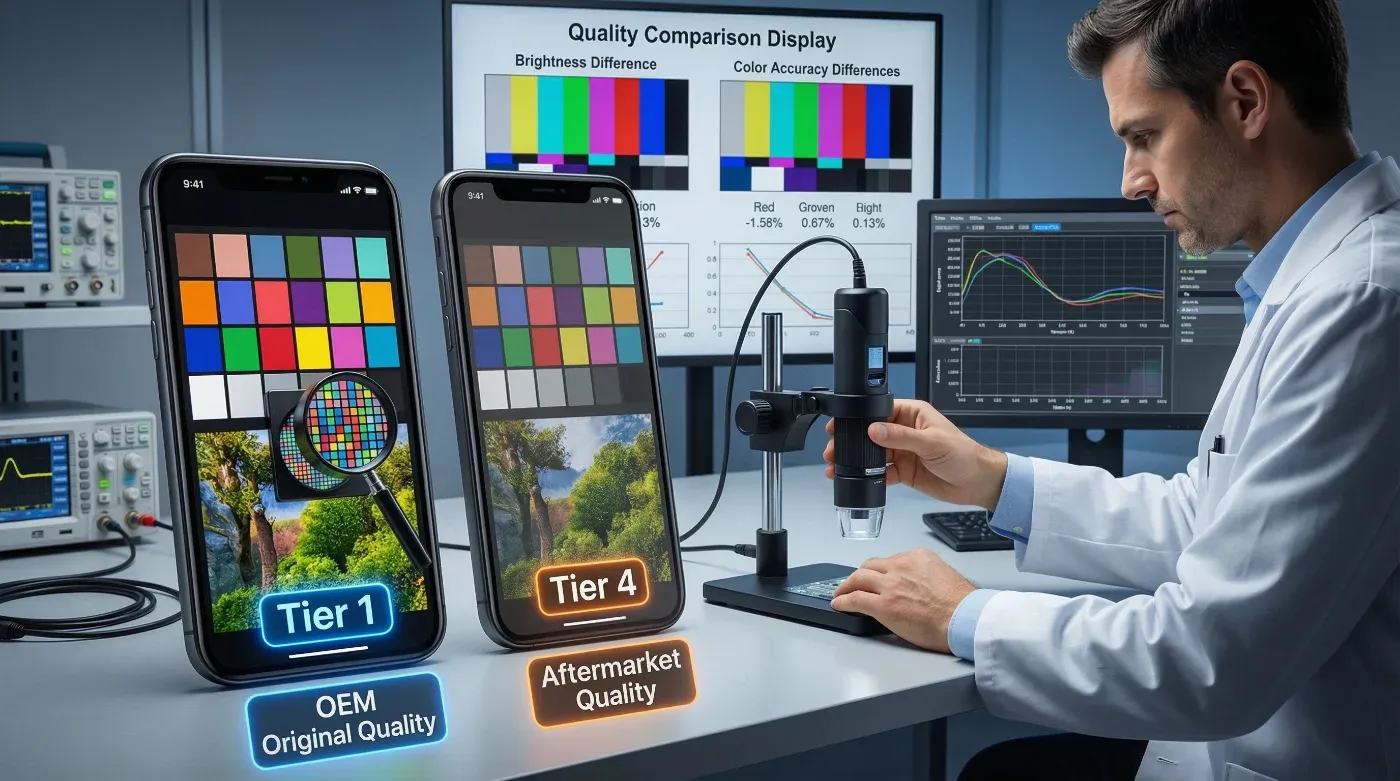

The Screen Grade Reality Check

Let me give you the straight talk on screen grades that suppliers won't tell you.

Soft OLED vs Hard OLED: The Real Math

Every supplier will tell you Hard OLED is "almost as good" as Soft OLED at a lower price. Here's what they won't tell you:

The numbers from 200+ repair shops I've worked with:

- Soft OLED average RMA rate: 0.8%

- Hard OLED average RMA rate: 2.4%

Let's do the math on 100 screens:

| Metric | Soft OLED | Hard OLED |

|---|---|---|

| Unit cost | $65 | $50 |

| Total purchase | $6,500 | $5,000 |

| Expected returns (at avg RMA) | 0.8 screens | 2.4 screens |

| Replacement cost | $52 | $120 |

| Labor for reinstalls ($20/screen) | $16 | $48 |

| True cost per screen | $65.68 | $51.68 |

Looks like Hard OLED still wins, right?

But here's what's missing: customer satisfaction. Those 2.4 returns per 100 screens aren't just numbers—they're angry customers, negative reviews, and lost referrals. One bad Yelp review costs you way more than $15 per screen.

My recommendation: Use Soft OLED for premium repairs where you charge accordingly. Use Hard OLED only for price-sensitive customers who understand the trade-off. Never use Hard OLED and charge Soft OLED prices—that's how you destroy your reputation.

The "原压" vs "后压" Distinction

This is insider terminology that separates professionals from tourists.

- 原压 (yuán yā): Original lamination. The glass and OLED panel were bonded at the factory as a unit.

- 后压 (hòu yā): Aftermarket lamination. Someone took a broken screen, removed the cracked glass, and bonded new glass to the original OLED panel.

后压 screens are cheaper because they're refurbished. They can be good quality if done properly, but:

- The lamination quality varies wildly.

- Dust particles can get trapped between layers.

- The touch response is often slightly worse.

If a supplier is selling 后压 screens at 原压 prices, that's fraud.

Ask directly: "这是原压还是后压?" If they hesitate or don't understand the question, find a new supplier.

The Questions That Reveal Everything

Here are the exact questions I ask every new supplier, and what their answers tell me:

Question 1: "这批屏幕的PWM频率是多少?有没有检测报告?"

(What's the PWM frequency of this batch? Do you have test reports?)

- Good answer: Specific number (e.g., "240Hz at low brightness, 480Hz at high brightness") plus offer to send documentation

- Bad answer: "What's PWM?" or "All our screens are high quality"

If they don't understand PWM, they don't understand quality control.

Question 2: "上一批货的退货率是多少?"

(What was the return rate on your last batch?)

- Good answer: Specific percentage, ideally below 1%

- Bad answer: "Very low" or "Almost zero" without numbers

Suppliers who track RMA rates are suppliers who care about quality. Suppliers who don't track are gambling with your business.

Question 3: "如果这批货有问题,换货流程是什么?"

(If this batch has problems, what's the exchange process?)

- Good answer: Clear policy with timeframes

- Bad answer: "We'll work it out" or "That won't happen"

Get the return policy in writing before you order. WeChat messages count as documentation in Chinese business disputes.

What to Do Monday Morning

Here's your action plan:

Step 1: Test your current inventory (30 seconds)

Pull out your phone right now. Grab one screen from your current stock. Do the slow-mo test at 25% brightness.

If it flickers, you now know why some customers complain about eye strain. Time to find a new supplier.

Step 2: Audit your supplier (5 minutes)

Send this message to your current supplier:

"请问你们最近一批iPhone 12屏幕的PWM频率是多少?退货率是多少?能提供检测报告吗?"

(What's the PWM frequency of your recent iPhone 12 screen batch? What's the return rate? Can you provide test reports?)

Their response will tell you everything you need to know about whether they're a quality-focused operation or just moving product.

Step 3: Before your next order

Don't accept any shipment without doing the 3-minute test protocol:

- Black room test (5 random screens)

- Slow-mo PWM test (25% brightness)

- Verify the supplier can answer basic quality questions

The Bottom Line

Every untested screen is a potential customer complaint waiting to happen. The 3 minutes you spend on proper testing will save you hours of dealing with returns, refunds, and reputation damage.

The repair shops that thrive aren't the ones with the lowest prices—they're the ones with the lowest return rates.

And the lowest return rates come from proper quality control, not luck.

At PRSPARES, we test every batch before shipping and can show you the documentation. Our RMA rate stays below 1% because we reject the screens that other suppliers would sell you. We've been in Huaqiangbei for over 10 years, and we speak the language—literally and figuratively.

Want screens that pass all these tests? Request samples and we'll include the test documentation so you can verify yourself. No commitment, no pressure—just take a look at what quality actually looks like.

Custom quotes within 24 hours. Because your reputation is worth more than a few dollars per screen.

This guide is based on 10+ years of experience sourcing screens from Huaqiangbei market. The testing protocols and supplier verification methods have been refined through thousands of transactions and feedback from repair shops worldwide.