Introduction: Why Supplier Selection Matters More Than Ever in 2025

The mobile repair industry has evolved dramatically over the past decade. According to recent industry analysis, the global mobile phone repair market is projected to reach $82 billion by 2027, growing at a compound annual growth rate of 6.4%. This explosive growth has led to a proliferation of parts suppliers, making it increasingly challenging to identify reliable partners who can deliver consistent quality and value.

![Featured Image: Professional warehouse facility with organized mobile phone parts inventory]

The stakes are higher than ever in 2025's competitive landscape. A single subpar component can result in costly reworks, damaged customer relationships, and potential liability issues that threaten your business's survival. With the increasing complexity of modern smartphones—including foldable displays, 5G components, and advanced biometric features—the margin for error has narrowed significantly.

The Financial Impact of Poor Supplier Selection:

- Direct Costs: Failed parts result in free re-repairs (labor + replacement parts)

- Reputation Damage: Each negative review can cost you 5-10 potential customers

- Inventory Issues: Stock inconsistencies lead to 15-20% lost revenue opportunities

- Hidden Expenses: Unexpected fees can erode profit margins by 8-12%

- Legal Risks: Non-compliant components may result in regulatory penalties

Beyond these immediate costs, poor supplier relationships can compromise your ability to scale operations, adapt to new technologies, and maintain the quality standards that customers expect in today's premium repair market.

This comprehensive 2025 guide provides repair shop owners with a systematic approach to evaluating and selecting cell phone parts suppliers, incorporating the latest industry standards, quality metrics, and best practices.

The Foundation: Understanding 2025 Industry Standards & Regulatory Requirements

Before diving into supplier evaluation, it's crucial to understand the regulatory landscape that shapes quality standards in the mobile repair parts industry.

Essential Certifications for 2025: The New Baseline

Mandatory Certifications (Non-Negotiable):

- ISO 9001:2015 - Quality Management Systems

- ISO 14001:2015 - Environmental Management Systems

- FCC Part 15 compliance - For all electronic components sold in the US market

- CE marking - Essential for European Union market access

- RoHS compliance - Restriction of Hazardous Substances

- UL 94 flammability rating - Critical for plastic components and casings

Advanced Quality Standards (Premium Suppliers):

- IATF 16949:2016 - Automotive-grade quality for electronics components

- AS9100D - Aerospace quality management

- IPC-A-610 - Electronics assembly standards

- REACH compliance - Chemical safety regulations for EU markets

- UN38.3 certification - Battery transport safety

The Complete Supplier Evaluation Checklist for 2025

Section 1: Quality Assurance & Certifications

![Quality Assurance Laboratory: Professional technician examining smartphone components with ISO 9001 certification badges visible]

| Certification | What It Means | Why It Matters |

|---|---|---|

| ISO 9001 | Quality management system | Consistent manufacturing processes |

| CE Marking | European safety compliance | Product meets EU standards |

| RoHS | Restriction of hazardous substances | Environmental compliance |

| UN38.3 | Battery transport safety | Required for lithium battery shipping |

| FCC | US electromagnetic compliance | Legal requirement for US market |

Section 2: Advanced Product Quality Assessment & Testing Protocols

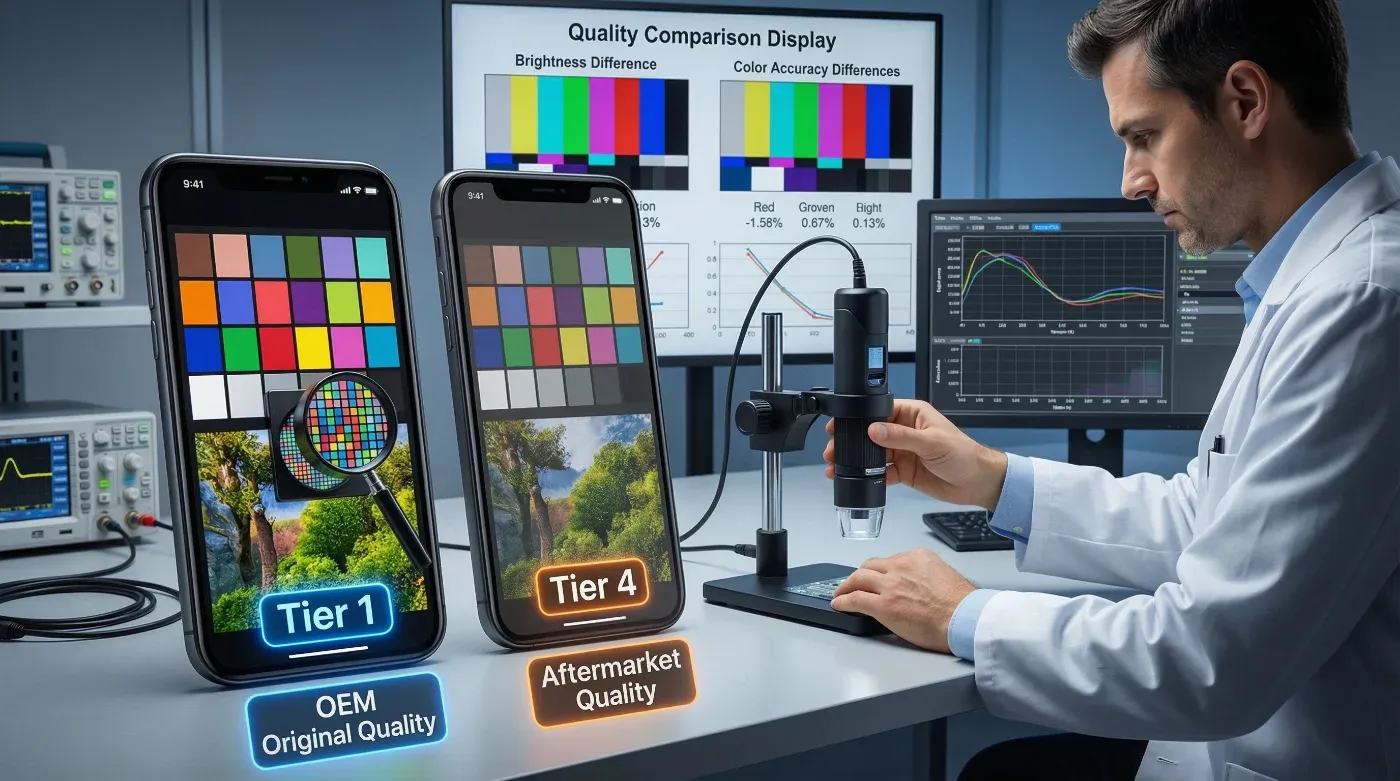

![Display Lab Testing: Professional testing equipment with color accuracy and brightness measurement tools]

Comprehensive Screen Quality Assessment:

Visual Performance Testing:

- Color accuracy verification with Delta E < 2.0 (professional grade)

- Brightness levels tested at minimum 400 nits (outdoor visibility)

- Contrast ratio verification (minimum 1000:1 for LCD, 1,000,000:1 for OLED)

- Viewing angle testing (minimal color shift at 178 degrees)

Enhanced Quality Grades for 2025:

| Grade | Description | Failure Rate | Best For | Price Premium |

|---|---|---|---|---|

| OEM Original | Genuine manufacturer parts | <0.1% | Premium repairs, warranty work | 100-150% |

| OEM-Quality Plus | Premium aftermarket exceeding OEM specs | <0.5% | Professional repairs, commercial clients | 80-120% |

| OEM-Quality | Aftermarket matching OEM specs | <1% | Standard professional repairs | 60-80% |

| Premium Copy | High-quality aftermarket with minor differences | <2% | Budget-conscious quality repairs | 40-60% |

| Standard Copy | Basic aftermarket quality | <5% | Lowest price point, economy repairs | 20-40% |

Section 3: Pricing Transparency & Structure

Volume Pricing Expectations:

| Order Size | Typical Discount |

|---|---|

| 10-25 units | 5-10% |

| 26-50 units | 10-15% |

| 51-100 units | 15-20% |

| 100+ units | 20-30% |

Section 4: Supply Chain Transparency & Advanced Logistics Management

![Global Supply Chain Logistics: Cargo containers, delivery trucks, freight airplane, and warehouse operations showing logistics network]

Shipping Method Comparison for 2025:

| Method | Transit Time | Cost Range | Best For | Risk Level | Tracking |

|---|---|---|---|---|---|

| Express Air | 1-3 days | $50-100/kg | Urgent repairs, critical inventory | Low | Real-time |

| Standard Air | 3-7 days | $15-40/kg | Regular inventory replenishment | Low | Daily |

| Ocean Freight | 15-35 days | $2-8/kg | Bulk orders, planned inventory | Medium | Weekly |

Section 5: Warranty & Return Policies

Standard Warranty Expectations:

| Part Type | Minimum Warranty | Ideal Warranty |

|---|---|---|

| Screens | 30 days | 90-180 days |

| Batteries | 30 days | 90 days |

| Charging Ports | 30 days | 60 days |

| Cameras | 30 days | 60 days |

| Small Parts | 14 days | 30 days |

Section 6: Customer Support & Communication

![Supplier Evaluation Meeting: Professional business team evaluating suppliers with quality metrics dashboard and performance evaluation charts]

| Factor | Poor | Acceptable | Excellent |

|---|---|---|---|

| Response Time | >48 hours | 24-48 hours | <24 hours |

| Language | Difficult to understand | Adequate | Clear, professional |

| Problem Solving | Defensive, unhelpful | Reactive | Proactive solutions |

| Availability | Limited hours | Business hours | Extended/24-7 |

Supplier Evaluation Scorecard for 2025

Use this comprehensive scorecard to compare potential suppliers objectively across multiple dimensions:

| Category | Weight | Supplier A | Supplier B | Supplier C |

|---|---|---|---|---|

| Quality & Certifications | 25% | /10 | /10 | /10 |

| Product Quality | 20% | /10 | /10 | /10 |

| Pricing Transparency | 15% | /10 | /10 | /10 |

| Shipping & Logistics | 15% | /10 | /10 | /10 |

| Warranty & Returns | 10% | /10 | /10 | /10 |

| Customer Support | 10% | /10 | /10 | /10 |

| Business Stability | 5% | /10 | /10 | /10 |

| Weighted Total | 100% | /10 | /10 | /10 |

Scoring Guide:

- 9-10: Exceptional, industry-leading

- 7-8: Good, meets professional standards

- 5-6: Acceptable, room for improvement

- 3-4: Below average, concerns exist

- 1-2: Poor, significant issues

Quick Reference: Supplier Red Flags

Immediate Disqualifiers:

- No verifiable business registration

- Refuses to provide samples

- No warranty policy

- Cash-only payment requirements

- Pressure for large upfront payments

Proceed with Caution:

- Very new company (<2 years)

- Prices significantly below market

- Limited communication channels

- No physical address

- Inconsistent information

Conclusion

Selecting the right cell phone parts supplier is one of the most critical decisions you can make for your repair business in 2025. By following this comprehensive checklist and evaluation framework, you can significantly reduce risk, improve your margins, and ensure consistent customer satisfaction.

Remember: the cheapest parts are rarely the best parts. Invest time in thoroughly vetting your suppliers using the standards and metrics outlined in this guide. Your business—and your customers—will thank you for it.

About PRSPARES:

PRSPARES is your trusted partner for high-quality mobile phone replacement parts. We meet all the criteria in this checklist and are committed to helping repair professionals succeed.